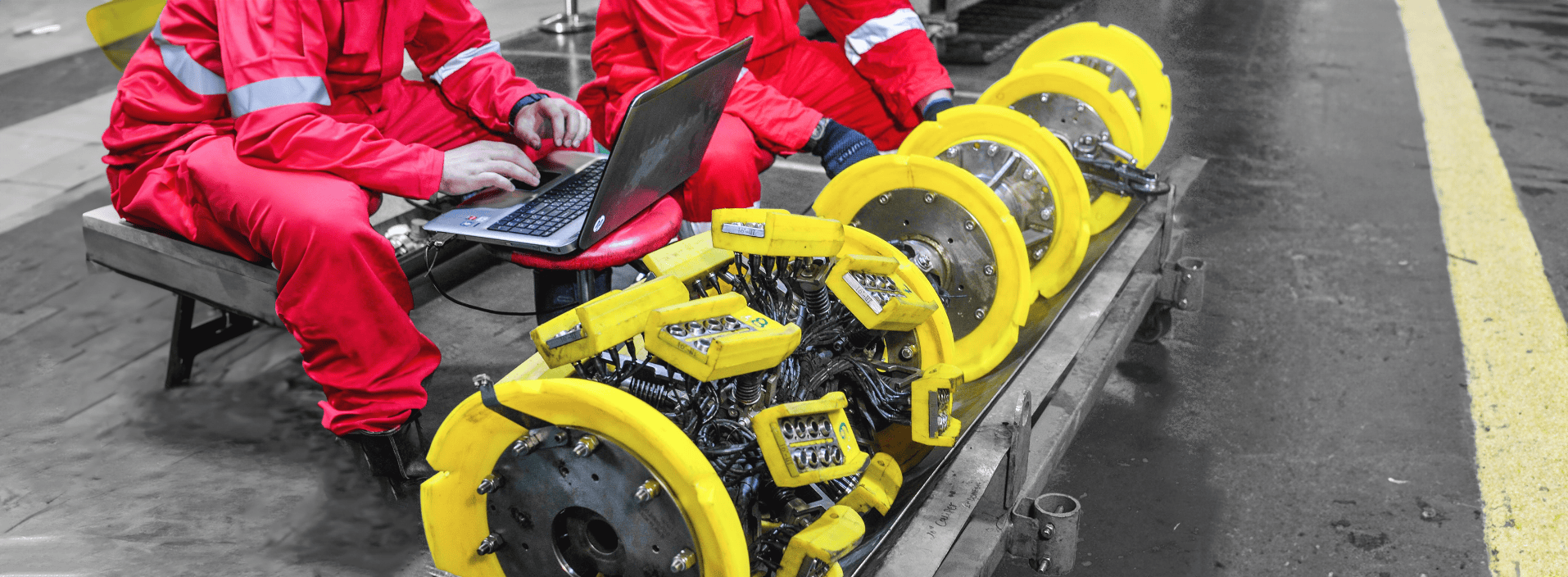

IN-LINE INSPECTION (ILI) SERVICES

Together with our esteemed partner, we proudly offer a comprehensive and highly successful track record in Inline Inspection (ILI) services, consistently rising to meet the rigorous demands and high standards of the contemporary pipeline industry:

Inspection

Targets a 95% Probability of Identification (POI) in pipeline inspections.

Innovation

Pioneers innovation with dedicated internal research and development

Integrity

Guarantees the effective management of pipeline integrity

We offer comprehensive In-line Inspection services such:

Preliminary Cleaning: Removal of deposits, corrosion, paraffin, dirt, and other substances that can affect diagnostic accuracy. This is achieved using special cleaning devices (scrapers or “pigs”).

2-Profilometry:

Geometric Inspection (Profilometry): Determining the geometry of the internal surface of the pipe and identifying defects such as dents and protrusions. This can be done using special geometric or calibration “pigs”.

3-Main Diagnostics:

Advantages:

Simple and cost-effective inspection.

Ability to measure pipe wall thickness and protective insulation coating, allowing calculation of residual strength and safe operational life of pipelines.

Capability to detect delaminations within the pipeline wall.

Note: UTIL is conducted only in single-phase mediums (water, kerosene).Ultrasonic In-Line Inspection (UT ILI): Applied to detect pipeline wall defects, including corrosion, cracks, localized thinning, and other anomalies.

Magnetic Flux Leakage (MFL ILI): Assessing the condition of pipe walls and detecting defects such as local metal losses, transverse weld joint abnormalities, patching and other external welded attachments, corrugation and other points of interest (external ferromagnetic mass, backing ring, pipeline material abnormality).

Advantages:

Low inspection cost by eliminating excessive diagnostic information.

Provides information on the location of unauthorized taps.